PID

PID is a type of closed loop control. It stands for proportion, integral, and derivative.

Proportion: Essentially it is how much to move by based on the error

Integral: Accumulated error over time, useful for getting to the goal after D is applied

Derivative: Change in error, useful to eliminate oscillations (up and down graphs)

To tune a mechanism to PID, the general rule is to use only P until oscillation occurs. Then, D is applied to smooth out the graph. Afterward, if the goal is never reached, (I and D is not always used) I can be used to give it just enough power.

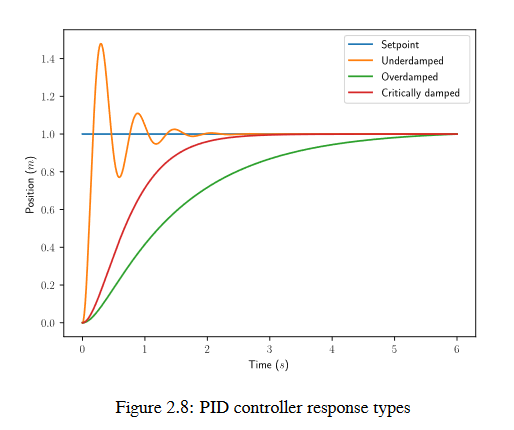

Example Graphs

In this example, it shows different graphs. Even though it does not show exact PID values, we can see the first graph is decent, but now D needs to be added. Green has too much D which causes it to be too slow getting to the setpoint. Red is what we are aiming for with a combination of D and I tuning after P alone.

Example Code

There are multiple classes in FRC that utilize PID, and we will show you a few examples.